Fifty years ago, leather would have been manufactured for the hundreds of thousands of small shoe factories still spread across Western Europe. Yet the majority of these have disappeared as shoemaking moved to low-wage countries. Those still left in Europe are highly skilled and provide exemplary quality like the famous Dutch brand Van Bommel. Van Bommel only uses leather from calves, and we met with its creative director, Floris van Bommel – one of three brothers that make up the ninth generation of this family business. We also meet Johan van Herck, a man who knows everything there is to know about calf’s leather. The conversation was fascinating.

Johan has retired, but started his profession in a time when it was quite common to travel long distances for the very best calf’s leather. With three colleagues, he would drive for two days to get to Le Bourget close to Paris for the leather trade show.

They even went further afield in search of the best tanneries in le Puy and Annonnay. That meant being away for weeks at a time. According to Johan, it was worth it.

He discovered the best quality leather in the south of France. He is not sure if it is the breed or the sun, but he also remembers when the popularity of leather from Dutch calves started to soar too.

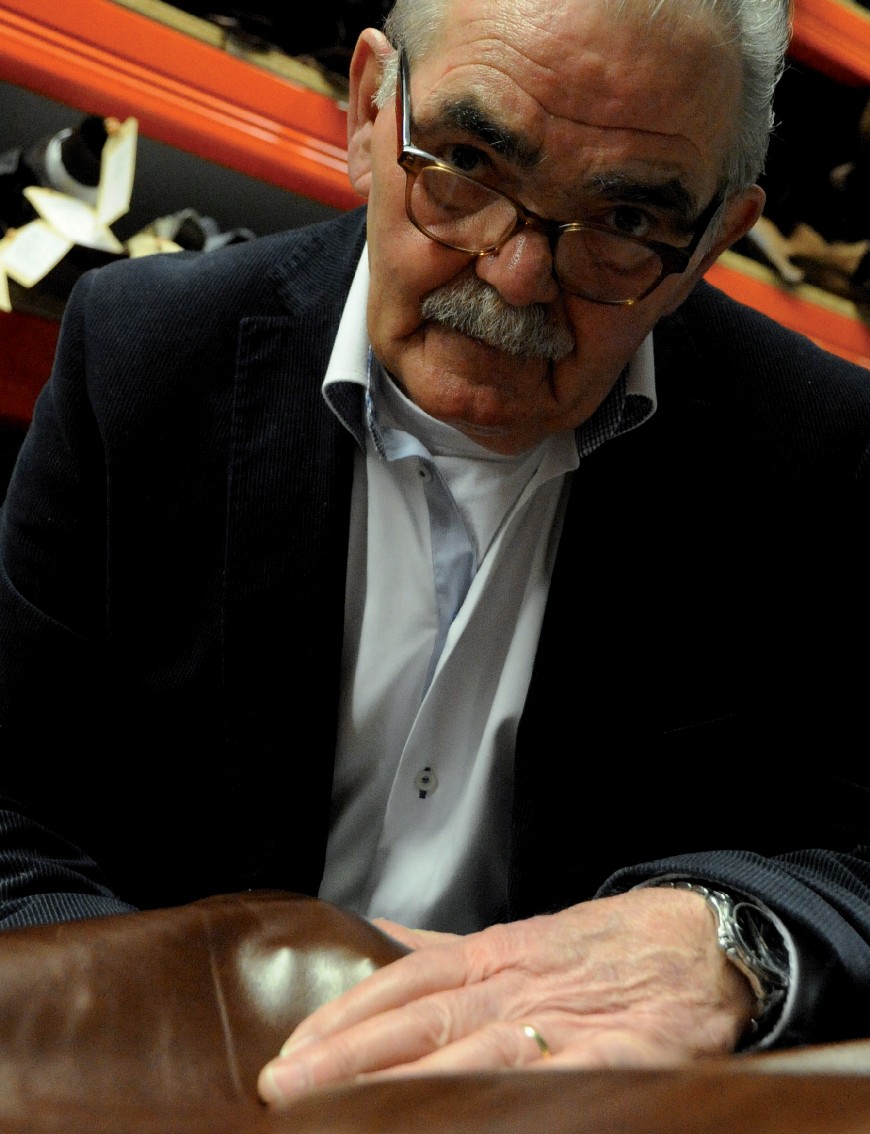

Johan adopted a strategy literally translated as overtaking. This meant inspecting each hide separately to assess its structure, whether or not it has creases in the neck – very important for a shoemaker and quite common in Swiss cows. The creases make a hide unusable to a shoemaker. Johan took us into the warehouse where he grabbed a roll of hide at random. “Rolled up calf” comments Floris in jest, but the craftsman touches it intensely, feeling every centimetre. According to Johan, every part of the hide feels different and works differently. If you look at areas that the animal has exercised a lot like the groin, the leather is more flexible. In contrast, other areas like the back are much tougher because they had very little exercise. This makes them the perfect choice for the toe.

One of the most important skills for a master shoemaker is knowing how to use every centimetre, knowing where to use it. Part of a shoe needs to be flexible. Part needs to be rigid and the flexible parts need to stretch and pull in the right direction. A shoe should never pull lengthwise for example, but give in the instep when it has been broken in and in the width is fine. Some shoes, like those made by Van Bommel, use three layers of leather, each performing its own task in maintaining the integrity of the shoe.

Calf’s leather

Leather is a material that has been used since the middle ages for things like horse tack, harnesses, book covers, wall paper, wineskin, shoes, boots, and gloves for falconers. Traditional tanning techniques require 80 litres of water and oak bark for every foot of leather (30x30cm). The flesh and hair is removed from the hide and the hides are stacked in large stone vats where they are mixed with ground oak bark. In this method, leather intended for the soles of shoes would stay in the vat for 2 years; leather for the uppers about eight months. Over the years however, these classic methods have been replaced by chrome tanning.

Today, different processes, technical one-upmanship, prints and colours have caused considerable competition between tanneries. It has also given customers like Van Bommel a warehouse overflowing with thousands of hides, all very different from one another. In days gone by, there would have been a few different kinds of leather like suede or lacquered. Now all of the choices are exhibited twice a year in Milan. Everyone who is anyone in the leather industry goes.

At Van Bommel, each hide is treated with due care and devotion. The average purchase price ranges from 50 to 60 euros per square meter, which is enough to make three pairs of shoes. This master shoemaker reserves the very best of hides for the very, very best and most expensive shoes, but that is quite understandable.

We asked Johan where he would look for the best leather: “The hide of a milk-fed calf used to give us perfect leather.” “And it’s remarkable how changes in the way we raise the calves has changed the way we make our shoes”, added Floris. “The new hides have more character. The slaughtering time for calves raised outside is very important. Calves slaughtered in May and June are the fattest, and in summer, the hide is thinner – veiny in the winter.”